August 12, 2025

3 European Brands Redefining Waste Materials Reuse

01 FRONT MATERIALS

Amsterdam, Netherlands

Founded in 2015 by Dutch designer Tom van Soest and business strategist Ward Massa, Amsterdam-based FRONT Materials—formerly known as StoneCycling—has emerged as a pioneer in circular construction. The company’s innovative product line began with van Soest’s graduation project at the Design Academy Eindhoven (2009–2011), where he explored upcycling demolition waste, leading to the company’s debut of its first product, the WasteBasedBrick, in 2015. FRONT Materials has since introduced panels made from paper waste, facade cladding made from 100 percent PVC waste, interior wall systems made from corn biomass, and even tiles grown from bacterium.

FRONT collaborates with partners like DC Bricks, Circular Matters, and Alusid to scale production and diversify its offerings. “We not only design and develop products that have a long lifespan (over 50 years) and contribute to a circular world, but we also prioritize building long-term and durable relationships with our customers, producers, suppliers, and other stakeholders,” the company writes in its “Rule Book.”

To date, the company has upcycled over 3.3 million kilograms of waste. Its vision is to help create cities constructed with materials that are reusable and demountable and absorb more carbon than they emit. FRONT is redefining the future of circular construction by not only making sustainable products but rethinking the systems behind them.

WasteBasedBrick

Each WasteBasedBrick is made of 60 percent waste sourced from construction, ceramics, and glass industries and is designed to meet the performance and aesthetic standards of modern architecture. Its counterpart, the WasteBasedSlip, offers a thinner cut of the same material, enabling reduced material use while maintaining visual consistency. The company aims to create products from 100 percent waste in the coming years.

BioBasedTiles

Launched in 2022, BioBasedTiles grow with the help of bacteria. Powered by the biomimetic methods of Biomason technology, the collection draws inspiration from coral and marine ecosystems. The tiles consist of 15 percent biocement and waste from granite production. They can grow in less than three days and are also 20 percent lighter and three times stronger than a concrete block. And unlike many ceramic tile alternatives, they don’t require kiln firing. That combined with the collection’s biofabrication process results in low-carbon, high-performance floor tiles.

Skip Tile

FRONT’s Skip Tile addresses the carbon-heavy process of ceramic tile production. While traditional methods rely on spray drying—a high-energy, CO₂-intensive step—Skip Tile eliminates this stage, using a low-energy, dry-granulation process that cuts emissions by over 50 percent. The result? A tile with both low impact and high design value. Produced by Alusid, the tile is suitable for any type of construction or renovation project.

02 AECTUAL

Amsterdam, Netherlands

Aectual is an architectural technology company redefining material use in the built environment through large-scale 3D printing and a fully circular design approach. Founded by and for architects Hans Vermeulen and Hedwig Heinsman in 2017, Aectual blends cutting-edge robotics, parametric design, and sustainable innovation to transform recycled and biobased waste into bespoke architectural products. Its portfolio includes divider systems, wall and flooring panels, storefront facades, and furniture—all made from materials like reclaimed ocean waste, wood waste, beverage cartons, consumer plastics, and plant-based fibers.

The company’s systems, such as Freeline and Origami, demonstrate that circular design and customization can go hand in hand. At the heart of Aectual’s mission is its Circular Takeback Service, a closed-loop system that helps eliminate waste and minimizes resource consumption. In an 82-page product playbook, Circular & Tailor-Made Interior Architecture Made Easy, the brand states: “Our unique Circular Service allows products to be returned, shredded, and reprinted into entirely new designs—turning yesterday’s projects into tomorrow’s solutions.” This ongoing cycle exemplifies true circularity, with the potential to reduce material use by up to 600 percent over 50 years.

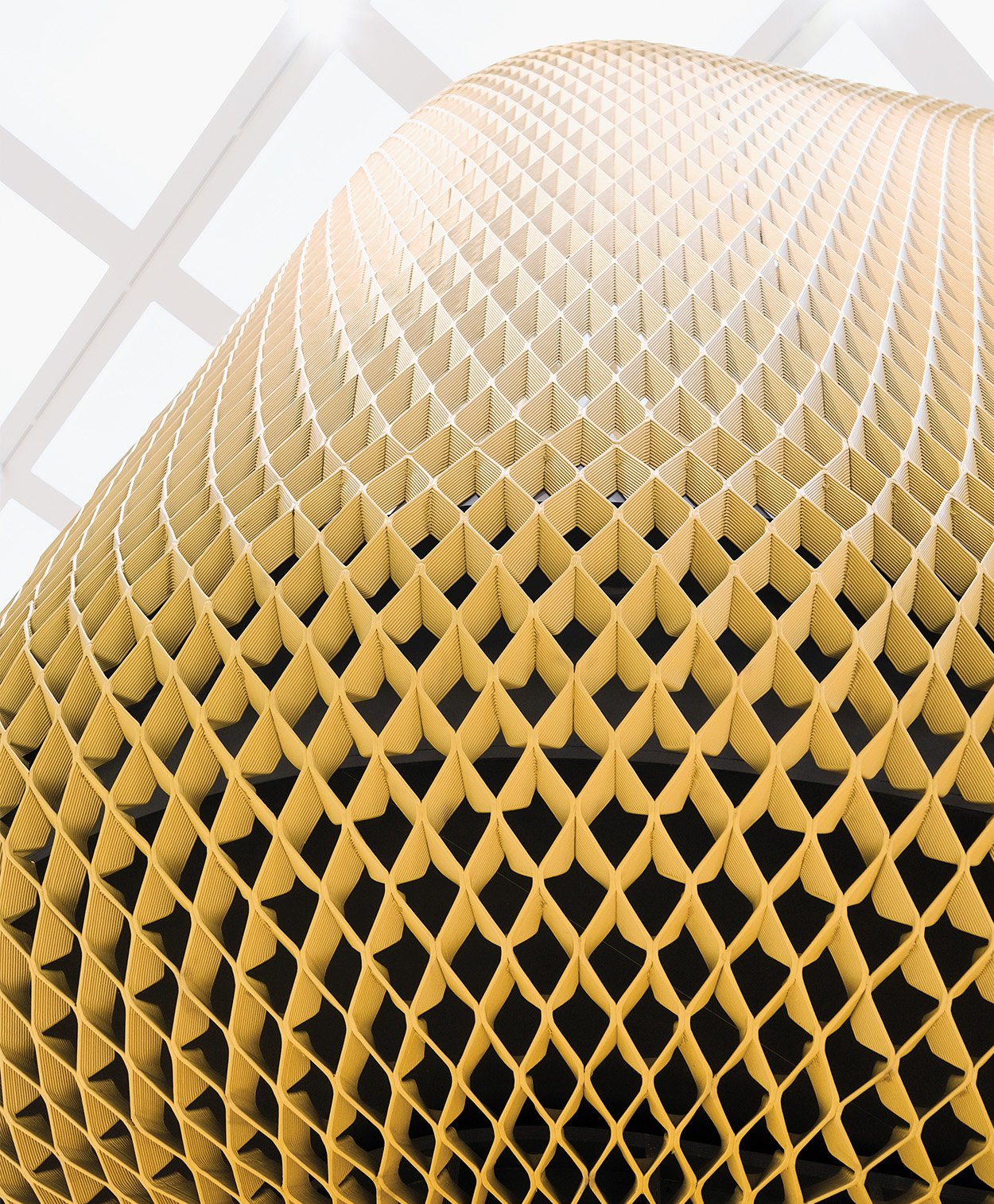

Aectual’s Origami panels, made from plant-based materials, were used in Dubai’s Museum of the Future to clad curved surfaces, offering flexible, semiopen designs that enhance light, shade, and privacy. With other products used worldwide by clients including Nike, BMW, and Amsterdam Airport, Aectual proves that sustainable, 3D-printed architecture is not just a possibility—it’s already here.

Origami

Aectual’s 3D-printed Origami wall panel system is a statement piece that also provides acoustic comfort. The system can bend in two directions, making it a great choice for cladding curved and double-curved surfaces, from walls to furniture.

Using Origami panels, Casper Schwarz of Amsterdam-based DLA Piper created a sculptural statement piece for the atrium of Strawinskyouse (above), serving the dual purposes of beauty and function. “I love to play with those opposites, and these panels allow natural light to filter through while offering enough seclusion for people inside,” Schwarz explains in a Q&A with Aectual, referring to the sculpture as a “champagne-colored bonbon.”

03 A:GAIN

Copenhagen, Denmark

Since its founding in 2015, Danish construction company a:gain has diverted more than 2.1 million kilograms of construction waste from landfills into high performance building products for B2B clients. Specializing in upcycling industrial by-products, demolition debris, and postconsumer waste, a:gain offers facades, flooring, acoustic panels, and partitions that can be used in a variety of settings. These products are designed to seamlessly replace conventional materials, offering a sustainable alternative without compromising on performance.

“Our approach is to identify suitable waste streams, including by-products, offcuts, and production waste, and repurpose them into functional and durable building materials at scale,” the company explains. “This helps mitigate environmental degradation by reducing demand for virgin materials and all the associated refining, transport, and manufacturing processes, as well as avoiding end-of-life processing of the waste.” In addition to waste stream research and tracking, a:gain conducts varied testing for fire resistance, sound insulation, and structural strength.

Beyond product development, a:gain emphasizes transparency and quality assurance, providing warranties and comprehensive documentation for its materials. By integrating advanced digital infrastructure and design tools, the company ensures that its circular products meet the stringent requirements of professional construction projects.

The company’s commitment to sustainability is evident in its product offerings, which have been utilized in over 100 projects across Denmark and internationally. Recently, a:gain contributed to the award-winning TRÆ building in Aarhus, supplying a range of circular products that significantly reduced the project’s carbon footprint, including discarded wind turbine blades, recycled facade panels, bricks, wood, and reclaimed double glazing.

In 2024, a:gain secured €4 million in seed funding to accelerate its mission of decarbonizing the construction sector. This investment underscores the growing demand for sustainable building solutions and validates a:gain’s innovative approach to material reuse.

Tystø

Tystø is a modular indoor partition system crafted from reclaimed glass units that were previously used as facade windows or indoor partition glass (opposite, left). Carefully removed from its original buildings, the glass is given new life as custom-built partitions that are screwed together and designed for disassembly.

Fusø

Fusø tabletops are made from 100 percent postconsumer waste from Carlsberg’s disposable DraughtMaster kegs, resulting in a black and green surface that resembles stone. Typically, kegs like these would not be recycled, so a:gain washes, sorts, and granulates the material to transform it into products including tabletops, bar cladding, and more.

Bronsø

Bronsø Thermo wood facade cladding is a thermally treated wooden product made from the discarded pine wood from the creation of wooden goods. A:gain is currently conducting a biodiversity study on Bronsø cladding, writing, “Increasing our knowledge of biodiversity impact will help us and our customers to make better-informed and more impactful decisions.”

Would you like to comment on this article? Send your thoughts to: [email protected]

Latest

Viewpoints

What Is and Is Not Biophilic Design?

The creator of the concept of Biophilic Design explains effective strategies that keep us healthy by bring us closer to nature.

Products

5 Smart Designs That Boost Brain Function

Discover products that blend neuroscience and biophilic design to boost focus, reduce stress, and support brain health.